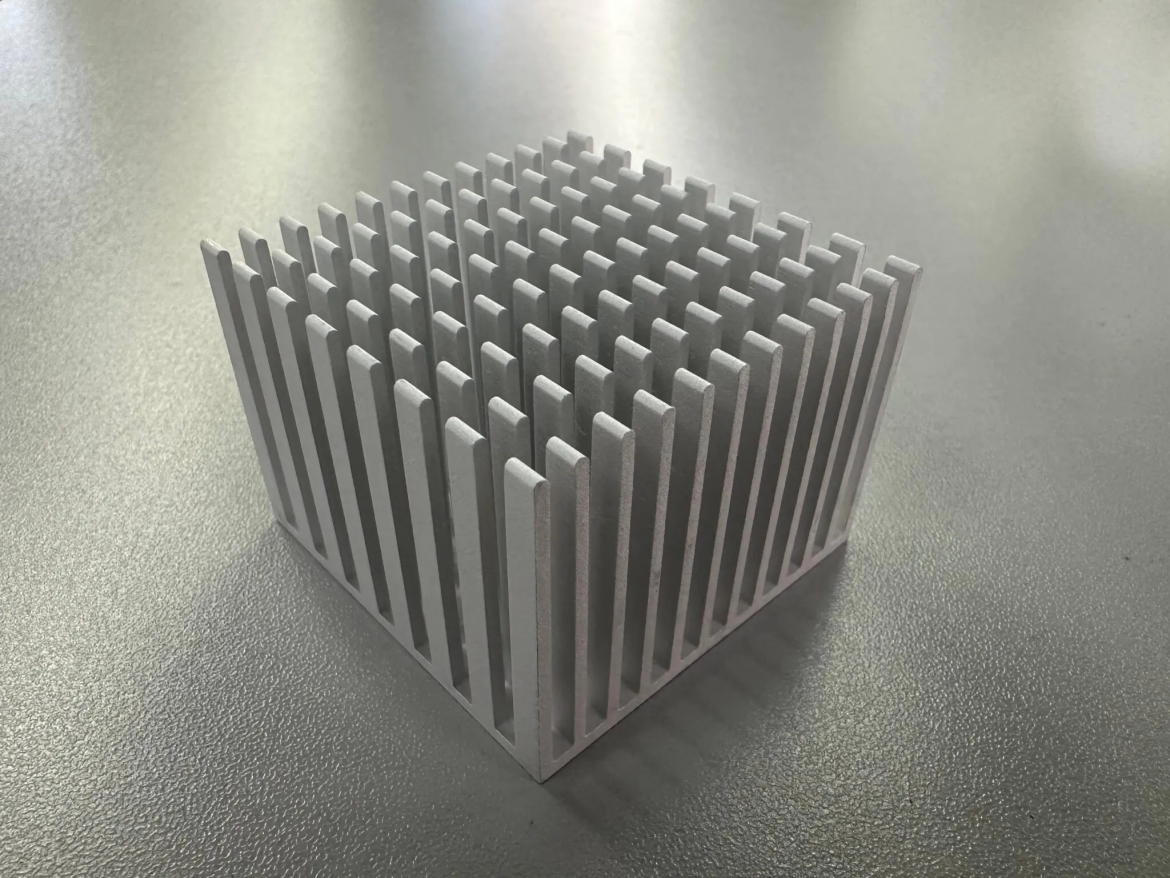

For applications ranging from LED lighting fixtures to renewable energy inverters, extruded heat sinks remain a cornerstone of cost-effective thermal solutions due to their rapid production cycles and adaptability to complex geometries. Dingmetal leverages advanced aluminum extrusion technology to manufacture extruded heat sinks that balance thermal performance with design flexibility, offering profiles from simple flat fins to multi-cavity structures with integrated mounting points. By optimizing alloy selection and post-extrusion treatments, the company delivers solutions that meet the durability and efficiency demands of industrial automation, telecommunications, and automotive electronics.

Alloy Selection for Environmental Adaptability

Dingmetal customizes material formulations to suit specific operating environments. For outdoor solar inverter applications, they utilize aluminum extrusions enhanced with magnesium-silicon alloying elements, which provide robust resistance to UV damage and thermal fluctuations, ensuring long-term structural stability. In high-humidity settings, such as HVAC systems, heat sinks are treated with chromate conversion coatings to enhance corrosion resistance while maintaining their thermal conductivity properties.

Precision Tooling for Complex Geometries

The company’s in-house die design team specializes in developing advanced multi-stage extrusion tools that can produce complex profiles with internal channels and stepped fins. For a medical diagnostic device manufacturer, Dingmetal designed an extruded heat sink featuring multiple parallel micro-channels within a compact profile, significantly increasing the surface area without enlarging the PCB footprint. Their automated extrusion presses operate at high speeds, ensuring consistent and precise fin heights throughout lengthy production runs.

Balancing Speed, Cost, and Performance in Thermal Design

Dingmetal’s extruded heat sinks provide a versatile solution for industries prioritizing rapid prototyping and volume scalability. By integrating material expertise, precision tooling, and surface engineering, the company enables manufacturers to achieve thermal targets without the lead times or tooling costs associated with die-casting or CNC machining. This approach proves particularly valuable in markets where product lifecycles are shrinking and energy efficiency regulations are tightening.