Rapid tooling fundamentally alters the manufacturing critical path by compressing mold fabrication from the traditional 4-8 weeks to as little as 48 hours. By leveraging additive manufacturing and soft tooling technologies, this approach allows engineers to validate designs, secure regulatory approvals, and enter the market before hard steel molds are even machined. For B2B professionals in the medical, automotive, and consumer electronics sectors, rapid tooling provides the essential agility to test functional parts in production-grade materials. This guide details the technical execution of these processes, enabling immediate bridge production for industries demanding speed and precision.

Accelerating Manufacturing with Additive Rapid Tooling

Rapid tooling transforms product development by shifting from subtractive CNC reliance to additive logic, enabling faster iterations and reducing financial risks during the pre-production phase.

Technical Mechanisms and Bridge Production Strategies

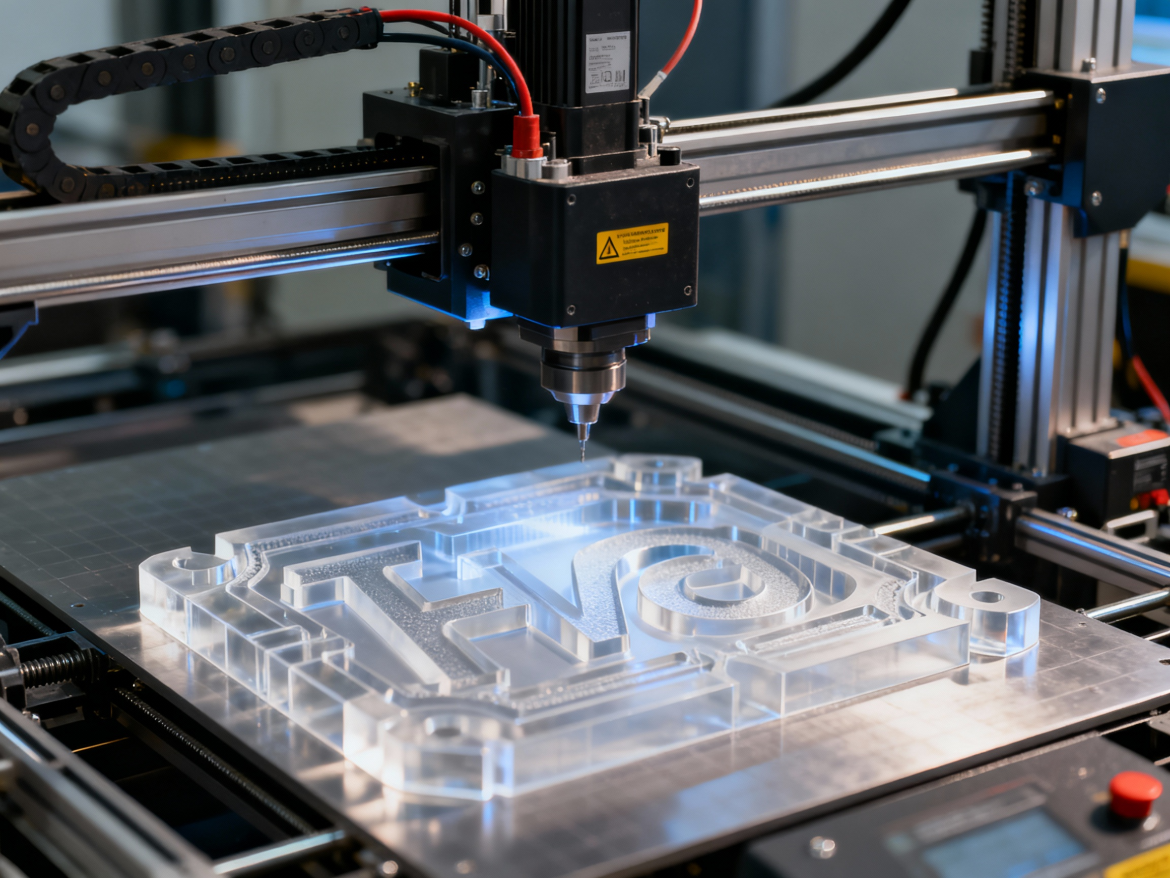

The technical shift from subtractive to additive manufacturing allows for the creation of complex mold geometries that were previously impossible or cost-prohibitive. Unlike traditional CNC machining, which has high removal rates and material waste, additive layer deposition uses photopolymer resins to build high-resolution mold shells. This “soft tooling” approach is economically viable for low-volume runs under 1,000 units, significantly reducing CapEx. For instance, rapid application tools enable engineers to implement physical functional testing within 24 hours of a design freeze. This speed facilitates a “fail fast” iteration model, where snap-fits and living hinges can be validated before cutting expensive P20 steel.

Furthermore, rapid tooling serves as a critical bridge production strategy. While waiting for durable steel molds to be fabricated—a process that can take months—manufacturers can utilize printed or soft molds to fulfill initial Purchase Orders (POs). This ensures that market entry is not delayed by tooling lead times. Advanced cooling solutions, such as conformal cooling channels engineered directly into the mold shell, further reduce cycle times, improving the dimensional stability of the injected parts. This capability is vital for mitigating supply chain disruptions via on-demand distributed manufacturing.

Optimizing Industry Applications from Medical to Automotive

Different industries leverage rapid tooling services to solve specific challenges. In the medical device sector, the customization of surgical guides and patient-specific hearing aid shells requires biocompatible materials like PEEK or Ultem. Rapid tooling allows for the validation of these materials in days, ensuring compliance with strict regulatory standards before mass production commitment. For consumer electronics, multi-material prototyping is essential. Engineers can simulate overmolding for soft-grip handles or test surface finishes for cosmetic approval, ensuring the final product meets aesthetic and functional requirements.

The automotive industry utilizes these technologies for legacy part replacement and digital inventory management. Instead of maintaining physical warehouses for spare parts, manufacturers can store digital files and produce spares on-demand using direct metal laser sintering (DMLS) or rapid injection molding. This reduces inventory costs and allows for the verification of lightweight structures in drone and UAV components. When analyzing volume thresholds, engineers must determine break-even points; while soft molds may only last 50 to 100 shots, they provide the necessary data to justify the transition to steel tooling for runs exceeding 100,000 units.

Livepoint Tooling: Your Partner for High-Precision Manufacturing

Livepoint Tooling delivers comprehensive manufacturing solutions, combining 23 years of expertise with advanced technologies to bridge the gap between concept and mass production for global clients.

Advanced Capabilities in Injection Molding and CNC

Livepoint Tooling excels in providing a seamless transition from prototype to final product through its integrated services. The company specializes in plastic injection molding, CNC machining, and rapid tooling services, supporting projects ranging from complex low-volume prototypes to high-volume manufacturing. Their facility is equipped to handle diverse requirements, including 3-axis milling, turning, grinding, and EDM (Electrical Discharge Machining). This vertical integration allows Livepoint to maintain tight tolerances of ±0.01mm, ensuring that even the most intricate designs are executed with precision. By offering both rapid prototyping and production-grade tooling, Livepoint enables clients to validate designs quickly and scale up efficiently without switching suppliers.

Certified Quality for Global Supply Chains

Quality assurance is paramount at Livepoint Tooling, evidenced by their robust certification portfolio. The company operates under ISO 9001:2015 and IATF 16949 standards, making them a trusted partner for the automotive and new energy sectors. Their expertise extends to producing critical components such as EV battery housings and high-voltage insulators. For the medical industry, Livepoint provides cleanroom-capable manufacturing environments, ensuring contamination control for sensitive devices. With over 10,000 tooling projects completed, their engineering team offers 24/7 support to optimize Design for Manufacturing (DfM), ensuring reliability and risk-free manufacturing for demanding applications worldwide.

Conclusion

Integrating rapid tooling into your manufacturing workflow converts the traditional bottleneck of mold making into a competitive accelerator. By partnering with a specialized provider like Livepoint Tooling, you gain access to the speed of additive manufacturing and the reliability of certified production processes. Contact our engineering team today to evaluate your project specifications and launch your product in days, not weeks.